Profibus PA Flexible Bus Cable

Profibus PA Bus Flexible Cable Application

PROFIBUS represents one of, if not the number one, the largest installed bases of fieldbus systems in the world. Using shielded twisted pair constructions, the two main application-specific profiles are Profibus PA, which optimized for discrete factory automation, and PROFIBUS PA, which optimized for process automation.

Profibus-PA was designed as a substitute for HART and 4 to 20mA signal transmission in the process industries. It uses function blocks designed around process industry requirements and uses the IEC 61158-2 physical layer, making it compatible with intrinsic safety circuits.

Profibus-PA links to the control architecture via Profibus-DP with a segment coupler or link as shown. Segment couplers are signal converters that adapt the RS-485 signals to the 61158-2 signal level. They are transparent from the bus protocol point of view. If segment couplers are used, the baud rate on the DP (RS-485) segment must be restricted to 45 Kbits/sec. The segment coupler also injects power into the PA network for the segment instrumentation.

This Profibus PA line is used in the area of process automation, among other things in the chemical industry. This cable is an economical solution for the cell and field area. For the information exchange between different automation systems as well as for communication with the connected decentralized field units, serial field bus systems are used. The types mentioned here are suitable for ex and not-ex installation and are equipped with a special PVC-jacket.

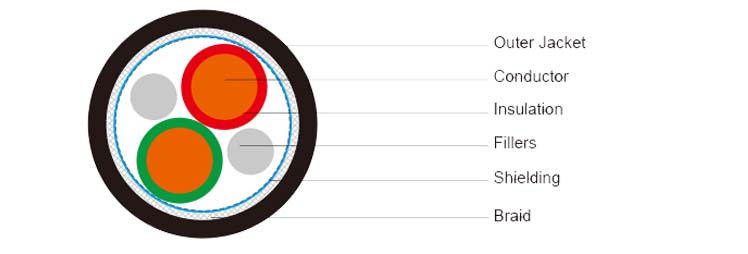

Profibus PA Bus Flexible Cable Construction

| Cable Construction | 1x2x1.6/3.2 mm |

| Inner Conductor Diameter 1 | Copper, bare (AWG 16/7) |

| Conductor Insulation | PE |

| Conductor Colors | red, green |

| Stranding Element | 2 conductors + 2 fillers stranded together |

| Shielding 1 | Polyester foil over stranded bundle |

| Shielding 2 | Polyester foil, aluminum-lined |

| Total Shielding | Copper braid, tinned |

| Outer Jacket Material | PVC |

| Outer Diameter | 7.6 mm ± 0.2 mm |

| Outer Jacket Color | Blue/Black |

Profibus PA Bus Flexible Cable Electrical Data

| Characteristic Impedance @ 31.25 KHz | 100 Ω ± 20 Ω | ||

| Conductor Resistance | 24.0 Ohm/km max. | ||

| Insulation Resistance | 1.00 GOhm x km min. | ||

| Mutual Capacitance@1KHz | 60.0 nF/km nom. | ||

| Working Voltage | 300 V | ||

| Test Voltage | 1.0 KV | ||

| Attenuation: | 39KHz | < | 2.7dB/km |

Profibus PA Flexible Bus Cable Technical Data:

| Weight | approximately 76.0 kg/km |

| Min. Bending Radius (Laying) | 18 x OD mm |

| Operating Temp.Range, min. | – 20 °C |

| Operating Temp.Range, max. | +70 °C |

| conductor stranding: | solid = 1x 1.05mm diameter flexible = 7x 0.25mm diameter |

| bend radius: | flexible versions = 10x overall diameter (O/D) hi-flex versions = 15x O/D |

| operating voltage: | solid = 100V, flexible & hi-flex = 300V |

| impedance: | 100 Ohms (±20Ω) @ 31.25 kHz |

| temperature range: | -40°C to +80°C operating (standard PVC versions) |

| core identification: | coloured red & green |

Profibus PA Flexible Bus Cable Specification

| AWG Size | No. of Cond. | Conductor

Stranding |

Approx Weight kg/km |

No. of Pairs | Nom. O.D

. of Cable (mm) |

| 18 | 2 | 7/26 | 50.75 | 6.43 | |

| 22 | 2 | 7/30 | 65.9 | 2 | 8.00 |

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.

Reviews

There are no reviews yet.