(N)TSCGECWOEU MV Trailing Cable

(N)TSCGECWOEU MV Mining Trailing Cable Application

(N)TSCGECWOEU Medium-Voltage Mining Trailing Cable is used for the connection of electrical equipment, in mines and underground excavations with hazardous environments under particularly high mechanical loads, e.g.high-voltage transformers on power lines in underground mining and tunneling.

The flexibility of the cable allows operating equipment to be moved while running. The phase-concentric earth conductor and the common concentric monitoring screen,e.g. in conjunction with a high-voltage protection circuit, make it possible to monitor the cable for insulation faults and damage that are produced by external effects.

These mining trailing cables are used in underground mines as well as in tunnels if monitoring of outer damages is required. The robust construction allows the cable to be used on mobile equipment, on energy lines, as well as for occasional reeling.

For particularly high mechanical stressing, the Braided armor of tinned steel wires is supplemented under the outer cable sheath. This armor serves as an external earthed screen.

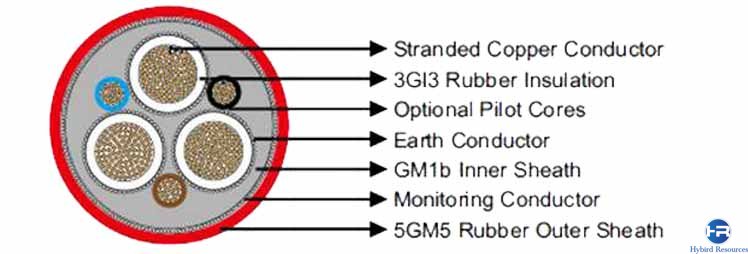

(N)TSCGECWOEU MV Mining Trailing Cable Construction

| Conductors | Flexible stranded copper conductor, class 5 according to DIN VDE 0295. |

| Inner Conductor Layer | Special rubber compound, conductive. |

| Insulation | Rubber type 3GI3. |

| Outer Conductor Layer | Special rubber compound, conductive, easy strippable. |

| Pilot Cores (optional) | Tinned copper conductor with EPR insulation. |

| Earth Conductor | Spiral of tinned copper wires. |

| InnerSheath | Rubber type GM1b. |

| Monitoring Screen/Armour | Braided of combined copper-steel wires; or wrap of copper and steel wires, copper tape in opposite direction, reinforcing tape. |

| Outer Sheath | Rubber type 5GM5. |

(N)TSCGECWOEU MV Mining Trailing Cable Technical Data

| Oil resistance | Yes |

| Flame retardant | Yes |

| Max. conductor temperature in service | 90°C |

| Limit surface temperature fixed installed | -40 .. 80°C |

| Limit surface temperature, flexible application | -25 .. 80°C |

| Bending factor when installed | 4(xD) |

| Dynamic bending radius | 7.5(xD) |

(N)TSCGECWOEU MV Mining Trailing Cable Specifications

6/10KV

| Number of Cores× Nominal Cross Section |

Minimium Overall Diameter |

Maximum Overall Diameter |

Nominal Weight |

| No.×mm² | mm | mm | kg/km |

| 3×25+3×16/3E+3×2.5ST+6UEL | 48 | 52 | 3500 |

| 3×35+3×16/3E+3×2.5ST+6UEL | 51 | 55 | 3750 |

| 3×50+3×25/3E+3×2.5ST+6UEL | 56 | 60 | 4720 |

| 3×95+3×50/3E+3×2.5ST+6UEL | 66 | 71 | 7260 |

| 3×120+3×70/3E+6UEL | 70 | 75 | 9700 |

| 3×150+3×70/3E+6UEL | 73 | 78 | 9950 |

12/20KV

| Number of Cores× Nominal Cross Section |

Minimium Overall Diameter |

Maximum Overall Diameter |

Nominal Weight |

| No.×mm² | mm | mm | kg/km |

| 3×25+3×25/3E+6UEL | 62 | 67 | 5800 |

| 3×95+3×50/3E+6UEL | 74 | 78 | 11000 |

| 3×120+3×70/3E+6UEL | 80 | 85 | 13000 |

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All the information is provided in good faith and is believed to be correct at the time of publication. When selecting cable accessories, please note that actual cable dimensions may vary due to manufacturing tolerances.

Reviews

There are no reviews yet.