MPYCY Shipboard Control and signal cables 150/250V

MPYCY Shipboard Control and signal cables 150/250V Application

MPYCY is intended for power circuit up to 250V, Lighting & Control circuit,also for fixed installation lighting & control in both explosion risk and safe areas, general purposes.

STANDARD APPLIED

Design guideline : JIS C 3410 (1999)

Material properties :

JIS C 3410 Insulation, EPR JIS C 3410 Sheath, PVC

Flame retardant :

IEC 60332-1

IEC 60332-3, Cat. A, ‘FA–’ type only

– Any other cable marking can be applicable, when purchaser required

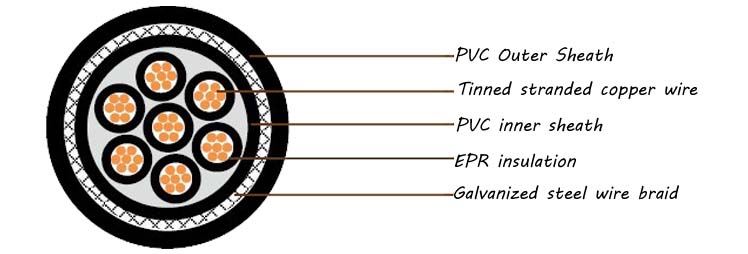

MPYCY Shipboard Control and signal cables 150/250V Construction

| Conductor | M | Tinned annealed stranded copper, class 2 according to IEC 60228 |

| Insulation | P | 85°C EPR as per JIS C 3401 |

| Cabling | Insulated conductors shall be cabled. Flame retardant & non-hygroscopic fillers may be used |

|

| Bedding | Y | PVC as per JIS C 3401 |

| Armor | C | Galvanized steel wire braid |

| Sheath | Y | PVC as per JIS C 3401 |

| Core identification | Black No. on white insulation /Black No. on white insulation, G/Y | |

| Outer sheath color | Black |

MPYCY Shipboard Control and signal cables 150/250V Technical Data

| Conductor cross-section | 1mm² |

| Conductor diameter | 1.3mm |

| Diameter over armour | 1.0mm |

| Average insulation thickness | 0.7mm |

| Rated Voltage Uo/U (Um) | 150 / 250 V |

| Max. DC resistance of the conductor at 20°C | 18.2Ohm/km |

| Test voltage | 1500V |

MPYCY Shipboard Control and signal cables 150/250V Specification

250V MPY,(FA-) MPY

| No. of cores |

Conductor | Thick. of insulation |

Thick. of bedding |

MPY,(FA-) MPY | ||||

| Size | Construction | O.D | Nom. overall dia |

Tolerance | Cable Weight |

|||

| mm² | No./mm | mm | mm | mm | mm | mm | kg/km | |

| 2 | 1 | 7/0.43 | 1.29 | 0.7 | 1.1 | 8.7 | 0.4 | 85 |

| 4 | 1 | 7/0.43 | 1.29 | 0.7 | 1.1 | 9.9 | 0.4 | 125 |

| 7 | 1 | 7/0.43 | 1.29 | 0.7 | 1.2 | 11.9 | 0.5 | 190 |

| 12 | 1 | 7/0.43 | 1.29 | 0.7 | 1.3 | 15.5 | 0.7 | 315 |

| 19 | 1 | 7/0.43 | 1.29 | 0.7 | 1.4 | 18.3 | 0.8 | 465 |

| 27 | 1 | 7/0.43 | 1.29 | 0.7 | 1.6 | 22.1 | 0.9 | 665 |

| 37 | 1 | 7/0.43 | 1.29 | 0.7 | 1.7 | 24.8 | 1 | 870 |

| 44 | 1 | 7/0.43 | 1.29 | 0.7 | 1.8 | 28 | 1.2 | 1160 |

| 77 | 1 | 7/0.43 | 1.29 | 0.7 | 2.1 | 35.9 | 1.5 | 1790 |

250V MPYC, (FA-) MPYC

| No. of cores |

Conductor | Thick. of insulation |

Thick. of bedding |

Dia. of steel wire |

MPYC,(FA-) MPYC | ||||

| Size | Construction | O.D | Nom. overall dia |

Tolerance | Cable Weight |

||||

| mm² | No./mm | mm | mm | mm | mm | mm | mm | kg/km | |

| 2 | 1 | 7/0.43 | 1.29 | 0.7 | 1.1 | 0.3 | 10 | 0.4 | 155 |

| 4 | 1 | 7/0.43 | 1.29 | 0.7 | 1.1 | 0.3 | 11.2 | 0.4 | 205 |

| 7 | 1 | 7/0.43 | 1.29 | 0.7 | 1.2 | 0.3 | 13.2 | 0.5 | 290 |

| 12 | 1 | 7/0.43 | 1.29 | 0.7 | 1.3 | 0.3 | 16.8 | 0.7 | 445 |

| 19 | 1 | 7/0.43 | 1.29 | 0.7 | 1.4 | 0.3 | 19.6 | 0.8 | 615 |

| 27 | 1 | 7/0.43 | 1.29 | 0.7 | 1.6 | 0.3 | 23.4 | 0.9 | 840 |

| 37 | 1 | 7/0.43 | 1.29 | 0.7 | 1.7 | 0.3 | 26.1 | 1 | 1070 |

| 44 | 1 | 7/0.43 | 1.29 | 0.7 | 1.8 | 0.3 | 29.3 | 1.2 | 1290 |

| 77 | 1 | 7/0.43 | 1.29 | 0.7 | 2.1 | 0.4 | 37.7 | 1.5 | 2180 |

250V MPYCY,(FA-) MPYCY

| No. of cores |

Conductor | Thick. of insulation |

Thick. of bedding |

Dia. of steel wire |

Thick. of covering |

MPYCY,(FA-) MPYCY | ||||

| Size | Construction | O.D | Nom. overall dia |

Tolerance | Cable Weight |

|||||

| mm² | No./mm | mm | mm | mm | mm | mm | mm | mm | kg/km | |

| 2 | 1 | 7/0.43 | 1.29 | 0.7 | 1.1 | 0.3 | 0.9 | 12 | 0.5 | 205 |

| 4 | 1 | 7/0.43 | 1.29 | 0.7 | 1.1 | 0.3 | 0.9 | 13.2 | 0.5 | 260 |

| 7 | 1 | 7/0.43 | 1.29 | 0.7 | 1.2 | 0.3 | 0.9 | 15.2 | 0.6 | 350 |

| 12 | 1 | 7/0.43 | 1.29 | 0.7 | 1.3 | 0.3 | 1 | 19 | 0.8 | 530 |

| 19 | 1 | 7/0.43 | 1.29 | 0.7 | 1.4 | 0.3 | 1.1 | 22 | 0.9 | 720 |

| 27 | 1 | 7/0.43 | 1.29 | 0.7 | 1.6 | 0.3 | 1.2 | 26 | 1 | 980 |

| 37 | 1 | 7/0.43 | 1.29 | 0.7 | 1.7 | 0.3 | 1.3 | 28.9 | 1.2 | 1240 |

| 44 | 1 | 7/0.43 | 1.29 | 0.7 | 1.8 | 0.3 | 1.3 | 32.1 | 1.3 | 1470 |

| 77 | 1 | 7/0.43 | 1.29 | 0.7 | 2.1 | 0.4 | 1.5 | 41.1 | 1.6 | 2470 |