FR-TPYC JIS C3410 Shipboard Armored Power&Lighting Cable

FR-TPYC JIS C 3410 Shipboard Armored Power&Lighting Cable Application

FR-TPYC JIS C 3410 Shipboard Armored Power&Lighting Cable is intended for power,lighting on shipboard,marine,and oil,gas off-shore platform where requires fire resistant features to ensure man safe and circuit integrity.

JIS C 3410 Shipboard Armored Power&Lighting Cable Standards and Designation

Designation:FR-DPYC, FR-TPYC,FR-FPYC

STANDARDS:JISC 3410-2010,

Fire Resistant:IEC 60331

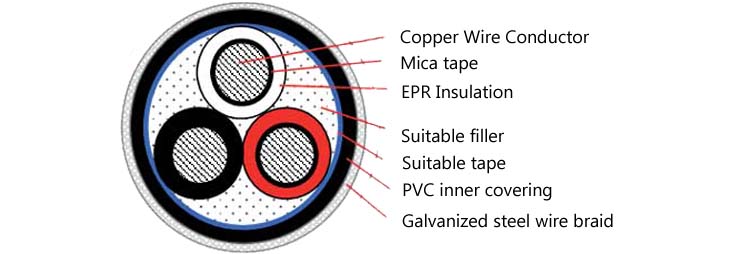

FR-TPYC JIS C3410 Shipboard Armored Power&Lighting Cable Construction

| Conductor | D(T,F,5,6,10) | Tinned annealed stranded copper, class 2 according to IEC 60228 |

| Insulation | P | 85°C EPR as per JIS C 3401 |

| Cabling | Insulated conductors shall be cabled. Flame retardant & non-hygroscopic fillers may be used |

|

| Bedding | Y | PVC as per JIS C 3401 |

| Armor | C | Galvanized steel wire braid |

| Core identification | 2C Black, White – 3C / 2C+E Black, White, Red/ Black, White, G/Y 4C / 3C+E Black, White, Red, Green /Black, White, Red, G/Y 5C and over Black No. on white insulation /Black No. on white insulation, G/Y |

|

| Outer sheath color |

Black |

JIS C 3410 Shipboard Fire Resistant Power&Lighting Cable Specification

0.6/1KV FR-DPYC

| Conductor | Thick. of insulation |

Thick. of bedding |

Dia. of steel wire |

(FA-) DPYC | ||||

| Size | Construction | O.D | Nominal overall dia. |

Tolerance | Cable weight (Approx.) |

|||

| mm² | No./mm | mm | mm | mm | mm | mm | mm | Kg / Km |

| 1.5 | 7/0.53 | 1.59 | 1 | 1.1 | 0.3 | 11.7 | 0.5 | 205 |

| 2.5 | 7/0.67 | 2.01 | 1 | 1.2 | 0.3 | 12.8 | 0.5 | 250 |

| 4 | 7/0.85 | 2.55 | 1 | 1.2 | 0.3 | 13.9 | 0.6 | 300 |

| 6 | 7/1.04 | 3.12 | 1 | 1.3 | 0.3 | 15.2 | 0.6 | 370 |

| 10 | 7/1.35 | 4.05 | 1 | 1.3 | 0.3 | 17.1 | 0.7 | 490 |

| 16 | 7/1.70 | 5.1 | 1 | 1.4 | 0.3 | 19.4 | 0.8 | 660 |

| 25 | 7/2.14 | 6.42 | 1.2 | 1.5 | 0.3 | 23 | 0.9 | 945 |

| 35 | 7/2.52 | 7.56 | 1.2 | 1.6 | 0.3 | 25.5 | 1 | 1200 |

| 50 | 19/1.78 | 8.9 | 1.4 | 1.8 | 0.3 | 29.4 | 1.2 | 1580 |

| 70 | 19/2.14 | 10.7 | 1.6 | 2 | 0.4 | 35.1 | 1.4 | 2300 |

| 95 | 19/2.52 | 12.6 | 1.6 | 2.1 | 0.4 | 39.1 | 1.6 | 2960 |

| 120 | 37/2.03 | 14.2 | 1.6 | 2.3 | 0.4 | 42.7 | 1.6 | 3600 |

| 150 | 37/2.25 | 15.8 | 1.8 | 2.4 | 0.4 | 46.8 | 1.7 | 4330 |

| 185 | 37/2.52 | 17.6 | 2 | 2.6 | 0.4 | 51.8 | 1.9 | 5330 |

0.6/1KV FR-TPYC

| Conductor | Thick. of insulation |

Thick. of bedding |

Dia. of steel wire |

(FA-) TPYC | ||||

| Size | Construction | O.D | Nominal overall dia. |

Tolerance | Cable weight (Approx.) |

|||

| mm² | No./mm | mm | mm | mm | mm | mm | mm | Kg / Km |

| 1.5 | 7/0.53 | 1.59 | 1.0 | 1.2 | 0.3 | 12.5 | 0.5 | 245 |

| 2.5 | 7/0.67 | 2.01 | 1.0 | 1.2 | 0.3 | 13.5 | 0.5 | 295 |

| 4 | 7/0.85 | 2.55 | 1.0 | 1.2 | 0.3 | 14.7 | 0.6 | 365 |

| 6 | 7/1.04 | 3.12 | 1.0 | 1.3 | 0.3 | 16.1 | 0.6 | 455 |

| 10 | 7/1.35 | 4.05 | 1.0 | 1.4 | 0.3 | 18.3 | 0.7 | 625 |

| 16 | 7/1.70 | 5.1 | 1.0 | 1.5 | 0.3 | 20.8 | 0.8 | 855 |

| 25 | 7/2.14 | 6.42 | 1.2 | 1.6 | 0.3 | 24.7 | 1.0 | 1240 |

| 35 | 7/2.52 | 7.56 | 1.2 | 1.7 | 0.3 | 27.4 | 1.1 | 1600 |

| 50 | 19/1.78 | 8.9 | 1.4 | 1.9 | 0.4 | 32.0 | 1.3 | 2200 |

| 70 | 19/2.14 | 10.7 | 1.6 | 2.1 | 0.4 | 37.6 | 1.5 | 3050 |

| 95 | 19/2.52 | 12.6 | 1.6 | 2.2 | 0.4 | 41.9 | 1.6 | 3980 |

| 120 | 37/2.03 | 14.2 | 1.6 | 2.4 | 0.4 | 45.8 | 1.7 | 4860 |

| 150 | 37/2.25 | 15.8 | 1.8 | 2.5 | 0.4 | 50.2 | 1.8 | 5870 |

| 185 | 37/2.52 | 17.6 | 2.0 | 2.7 | 0.4 | 55.5 | 1.9 | 7230 |

| 240 | 61/2.25 | 20.25 | 2.2 | 3.0 | 0.4 | 62.7 | 2.3 | 10100 |

0.6/1KV FR-FPYC

| Conductor | Thick. of insulation |

Thick. of bedding |

Dia. of steel wire |

(FA-) FPYC | ||||

| Size | Construction | O.D | Nominal overall dia. |

Tolerance | Cable weight (Approx.) |

|||

| mm² | No./mm | mm | mm | mm | mm | mm | mm | Kg / Km |

| 1.5 | 7/0.53 | 1.59 | 1.0 | 1.2 | 0.3 | 13.4 | 0.7 | 370 |

| 2.5 | 7/0.67 | 2.01 | 1.0 | 1.2 | 0.3 | 14.4 | 0.7 | 440 |

| 4 | 7/0.85 | 2.55 | 1.0 | 1.3 | 0.3 | 16.0 | 0.8 | 550 |

| 6 | 7/1.04 | 3.12 | 1.0 | 1.3 | 0.3 | 17.4 | 0.9 | 680 |

| 10 | 7/1.35 | 4.05 | 1.0 | 1.4 | 0.3 | 19.9 | 1.0 | 940 |

| 16 | 7/1.70 | 5.1 | 1.0 | 1.5 | 0.3 | 22.6 | 1.1 | 1280 |

| 25 | 7/2.14 | 6.42 | 1.2 | 1.7 | 0.3 | 27.3 | 1.4 | 1860 |

| 35 | 7/2.52 | 7.56 | 1.2 | 1.8 | 0.3 | 30.2 | 1.5 | 2400 |

| 50 | 19/1.78 | 8.9 | 1.4 | 2.0 | 0.4 | 35.6 | 1.8 | 3300 |

| 70 | 19/2.14 | 10.7 | 1.4 | 2.1 | 0.4 | 40.2 | 2.0 | 4580 |

| 95 | 19/2.52 | 12.6 | 1.6 | 2.4 | 0.4 | 46.5 | 2.3 | 5970 |

| 120 | 37/2.03 | 14.2 | 1.6 | 2.5 | 0.4 | 50.8 | 2.5 | 7290 |

| 150 | 37/2.25 | 15.8 | 1.8 | 2.7 | 0.4 | 56.1 | 2.8 | 8810 |

| 185 | 37/2.52 | 17.6 | 2.0 | 2.9 | 0.4 | 61.9 | 3.1 | 10850 |

For more specs,pls contact us.