NSSHCGEÖU High Tensile Stress Coal Cutter Cable 0.6/1KV

NSSHCGEÖU High Tensile Stress Coal Cutter Cable 0.6/1KV Application

NSSHCGEÖU Longwall / Coal Cutter Cables are used for the connection of mobile machines under extremely high mechanical loads, predominantly in mining situations,e.g. for coal-cutting machines, suitable for extreme bending loads under high tensile stress.

The phase-concentric monitoring shield and the common concentric earth conductor, in conjunction with appropriate monitoring equipment, make it possible to monitor the cable for insulation faults and damage resulting from external influences. The cable can be delivered with 2, 3, or 6 pilot cores.

These NSSHCGEÖU cables comply with DIN VDE 0250 part 812 Standards.

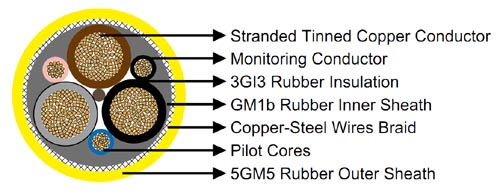

NSSHCGEÖU High Tensile Stress Coal Cutter Cable 0.6/1KV Construction

| Conductor | Finely stranded copper conductor, tinned, Class 5 (refer also to DIN VDE 0295) |

| Protective-earth conductor | Steel/Cu stranded braid between the inner and outer sheath |

| Control core | double-concentric control/monitoring conductor elements in the outer interstice |

| Insulation: | basic material EPR, compound type: 3GI3 (refer also to DIN VDE 0207, Part 20) |

| Electrical field control | Outer semiconductive layer of semiconductive cold-strippable rubber |

| Core arrangement | Three main cores laid-up, with double-concentric control/monitoring conductor elements in the outer interstice; length of lay approx. 6 x D |

| Inner sheath | Vulcanized rubber inner sheath; basic material EPR, compound type: GM1b |

| Reinforced braid | Braid of steel/copper wires in a vulcanized bond between inner and outer sheath |

| Outer sheath | basic material PCP, compound type: 5GM5, color yellow, abrasion, and tear resistant, oil resistant and flame retardant |

NSSHCGEÖU Low Tensile Stress Coal Cutter Cable 0.6/1KV Technical Data

| Rated Voltage Uo/U (Um) | 0.6/1 kV |

| Max. conductor temperature in service | 90°C |

| Max. short-circuit temperature of conductor: | 200°C |

| Limit surface temperature fixed installed | -40°C~ 80°C |

| Limit surface temperature, flexible application | -25°C ~ 80°C |

| Oil resistance | Yes, DIN VDE 0473, part 811-2-1, par. 10, EN 60811-2-1, IEC EN 60811-1-2 |

| Flame retardant | Yes, DIN VDE 0482, EN/IEC 60332-1-2 |

| Dynamic bending radius | 4(xD) |

| Static bending radius | 1.5(xD) |

NSSHCGEÖU Low Tensile Stress Coal Cutter Cable 0.6/1KV Specifications

| No. of cores x cross-section | Outer- Ø | Cable weight approx. | Tensile strength |

| n x mm2 | mm ± 10% | kg/km | N |

| 3×25/16KON+3x(1.5ST KÖN/1.5 UL KON) | 38 | 2850 | 1125 |

| 3×35/16KON+3x(1.5ST KÖN/1.5 UL KON) | 43 | 3070 | 1575 |

| 3×50/35KON+3x(1.5ST KÖN/1.5 UL KON) | 46 | 4010 | 2250 |

| 3×70/35KON+3x(1.5ST KÖN/1.5 UL KON) | 53 | 4970 | 3150 |

| 3×95/50KON+3x(1.5ST KÖN/1.5 UL KON) | 58 | 6580 | 4275 |

| 3×120/70KON+3x(1.5ST KÖN/1.5 UL KON) | 61 | 7600 | 5400 |

| 3×150/70KON+3x(1.5ST KÖN/1.5 UL KON) | 65 | 9350 | 6750 |

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All the information is provided in good faith and is believed to be correct at the time of publication. When selecting cable accessories, please note that actual cable dimensions may vary due to manufacturing tolerances.

Reviews

There are no reviews yet.