NSSHOU 3E+ST Low Voltage Mining Cable 0.6/1KV

NSSHOU 3E+ST Low Voltage Mining Cable 0.6/1KV Application

NSSHOU 3E+ST is heavy-duty, tough rubber, flexible cables manufactured for use in Mining, Drilling and Tunnelling applications with a voltage rating of 600/1000V. Flame-retardant, UV, abrasion, cut, notch and tear-resistant, they offer good resistance to oil and greases, and can be used as power supplies where high levels of mechanical stress and abrasion are expected.

NSSHOU 3E+ST is heavy duty tough rubber flexible cable with or without individually earth screened cores for dynamic or static applications in aggressive environments. Flame retardant,abrasion, cut, notch and tear resistant. Good resistance to oil and fats. Suitable for installation in dry, damp, wet and in hazardous environments. For power supplies where high levels of mechanical stress and abrasion are expected.

NSSHOU 3E+ST Can be permanently submersed in fresh water, salt water, storm water,oily water and sewage contaminated water to a depth of 100 metres. Suitable for indoor and outdoor applications.

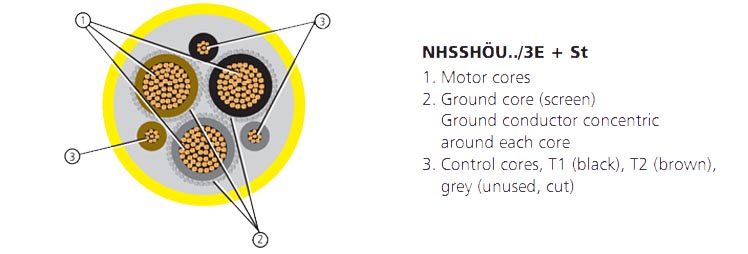

NSSHOU 3E+ST Low Voltage Mining Cable 0.6/1KV Construction

| Conductor: | Flexible red copper conductor Cl. 5, acc to IEC 60228, DIN VDE 0295 |

| Insulation: | rubber EPR type 3G13 |

| Colour cores: | acc. to DIN VDE 0293-308, HD 308 S2 3 phase cores: brown-black-gray |

| Screen | |

| POWER 3E: | braid earth-conductor over the insulation |

| KON: | concentric between the inner and outer sheath |

| Inner sheath: | EPR compound GM1B |

| Outer sheath: | yellow, PCP compound 5GM5 |

NSSHOU 3E+ST Low Voltage Mining Cable 0.6/1KV Technical Data

| Fixed installation: | – 40°C + 80°C |

| Flexible installation: | – 25°C + 80°C |

| Nominal voltage: | Uo/U 0.6/1 kV |

| Test voltage: | 3000 V |

| Max. operating voltage: | A.C. Uo/U = 0,7/1,2 kV D.C. Uo/U = 0,9/1,8 kV |

| Insulation resistance: | > 20 MOhm x km |

| Tensile strength static: | 15 N/mm2 |

NSSHOU 3E+ST Low Voltage Mining Cable 0.6/1KV Specification

| No. of cores x cross-section

(n x mm2) |

Outer-Øca. mm ± 10% | Cable weight approx.

(kg/km) |

Tensile strength

(N) |

| 3×2.5+3×2.5/3E+3×1.5ST | 18.5 | 520 | 113 |

| 3×4+3×4/3E+3×1.5ST | 19.5 | 600 | 180 |

| 3×6+3×6/3E+3×1.5ST | 20 | 670 | 270 |

| 3×10+3×10/3E+3×2.5ST | 23.5 | 1010 | 450 |

| 3×16+3×16/3E+3×2.5ST | 27 | 1290 | 720 |

| 3×25+3×16/3E+3×2.5ST | 31 | 1780 | 1125 |

| 3×35+3×16/3E+3×2.5ST | 35 | 2300 | 1575 |

| 3×50+3×25/3E+3×2.5ST | 40.5 | 3200 | 2250 |

| 3×70+3×35/3E+3×2.5ST | 45 | 4010 | 3150 |

| 3×95+3×50/3E+3×2.5ST | 51 | 5100 | 4275 |

| 3×120+3×70/3E+3×2.5ST | 57 | 6510 | 5400 |

| 3×150+3×70/3E+3×2.5ST | 63 | 7600 | 6750 |

| 3×185+3×95/3E+3×2.5ST | 67.5 | 9400 | 8325 |

Options:

Further numbers of cores and cross-section upon request

Special cold resistant compound.

Photographs are not to scale and do not represent detailed images of the respective products