What is welding cable?

Welding Cable, so-called welding lead, is intended for supplying power to an electrode in an electrical arc welding application. It is a specially designed metal rod, that conducts a charge. The charge carried by the electrode is required to make an electric arc, that heat sources, between the electrode and the metals or other welding materials, being welded. welding cable usually is the electrical cable to carrying welding current.

Welding cables are specially designed cable for use in secondary circuits of electric welders. Welding cable is a popular portable cord that is used in various welding applications as well as many power supply applications where some flexibility is required.

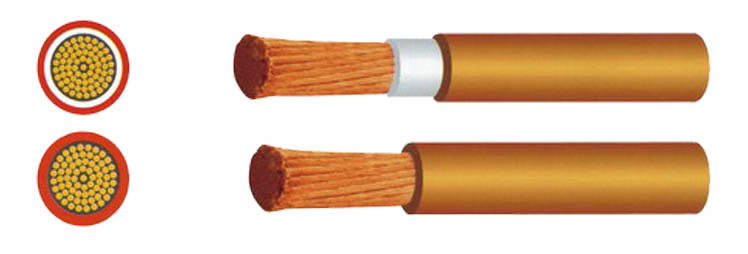

It consists of a series of fine stranded copper wires wrapped by a non-conductive, wear-resistant jacket (typically some type of synthetic or natural rubber of various colors). Welding cable typically consists of a single core, Class 5 or 6 stranded conductor that usually ranges in size from 10mm2 to 240mm2 and insulation of EPDM or neoprene thermoset materials. The rubber compound jacket for welding cable is heat resistance, oil resistance, and non-flame retardant. This product is applicable to the ground voltage AC not more than 200V and pulse DC peak 400V welding machine with a secondary circuit connection and connection of an electric welding machine. The maximum operating temperature of the cable is 65℃. Welding cable is notable for its flexibility and durability, and many automatic and manual welding applications require the cable to hold up to repeated movement over rough surfaces.

Welding Applications

The two main types of electric welding, are resistance welding and arc welding. In both welding types, welding cable is used to power the electrode.

Resistance welding is the process of fusing two overlapped metals together by the current resistance of the overlapped metals. The metals are placed between two electrodes (also known as welding points) and low-voltage, high-current electricity is passed from one point to the other. The metals resist the current and the heat fuses the metals into one piece.

Arc welding is the process of using a welding power feeder to produce an electric arc between an electrode and the base material, also called workpiece. and then the electric arc melts the electrode and the workpiece. The electric arc is usually protected by some type of shielding gas, like argon, between the electrode and the weld surface. Arc welding processes may be manual, semi-automatic, or fully automated. Today it remains an important process for the fabrication of steel structures and vehicles.

Welding cable Current Carrying Capability

Welding cable Ampacity, also known as amperage capacity, current capacity, or amp ratings, refers to the maximum amount of electrical current that a cable can safely conduct.

Amperage, also known as current, is a measure of the number of charged particles (coulombs) moving past a fixed point in one second. Another way to think of it is that amperage is the measure of the volume of charged particles moved per second relative to some fixed point, or the volumetric flow rate through a conductor.

Different welding cables running on the same voltage (e.g. 600V) will have different amp ratings depending on several factors including cable length, gauge, insulation temperature rating, and what kind of machine it is connected to.

100V H01N2-D Welding Cable Current Table

| Nominal cross-sectional area of conductor | Capacity of conductor at 60% duty cycle | Capacity of conductor at 35% duty cycle |

| mmq | Ampere | Ampere |

| 10 | 108 | 122 |

| 16 | 175 | 230 |

| 25 | 230 | 300 |

| 35 | 290 | 375 |

| 50 | 365 | 480 |

| 70 | 460 | 600 |

| 95 | 560 | 730 |

| 120 | 650 | 850 |

The welding cable must not be loaded current more than the above listed. Overloading your welding cable, also called thermal overloading, means running more current through the cable more than its rated ampacity allows. This causes overheating and can deteriorate or melt the insulation, leaving exposed wires that can get damaged or cause electrocution.

How to Calculate Current for your welding cable

Since most power distribution systems deliver power at fixed voltages, we can calculate amperages based on the given voltage and how much power (watts) we need to use to power a machine using the equation P = V x I where

P = power (watts = joules/sec)

V = voltage (V = joules/coulomb)

I = amperage (I = coulomb/sec)

As you can see, using P = V x I, the units for coulombs in voltage and amperage cancel leaving the units for power, which is joules/sec. Thus, if the amount of power used stays constant, doubling the voltage will halve the amperage and vice versa. (For AC circuits the equation is slightly more complicated. P = V x I x PF where PF stands for the power factor, which is always between 0 and 1.)

NOTE: The equation for resistance is R = V / I and power is P = V x I. By increasing voltage and reducing the current, the resistance increases. In order to keep the power constant higher voltages actually require cables with more resistance. This means that higher voltages allow for thinner and longer cables since thicker and shorter cables have less resistance. (This is also why high voltages are used for power transmission.)

Welding Cable Size Chart

Our welding cable size chart is available to help you choose the right wire for your applications. The welding cable size chart below includes the wire gauge, length of the wire, diameter, weight, technical details, and color of available.

The important specs to go by when choosing the appropriate wire that is suitable for your applications are the size, amp, voltage rating and the required length. If you have the specifications available, you can simply choose the appropriate wire with your specs from the welding cable size chart. If one or more of the criteria is not defined on the welding cable size chart, it would be safe to go with a wire that corresponds to the larger size from your required specs.

100V H01N2-D Welding Cable Technical Data

| Nominal cross sectional area of conductor | Maximum diameter of wire of conductor | Thickness of covering | Mean overall diameter | Maximum conductor resistance at 20°C |

| mmq | mm | mm | mm | Ohm/Km |

| 10 | 0,21 | 2 | 8,2 | 1,91 |

| 16 | 0,21 | 2 | 9,2 | 1,21 |

| 25 | 0,21 | 2 | 10,7 | 0,78 |

| 35 | 0,21 | 2 | 12,4 | 0,554 |

| 50 | 0,21 | 2,2 | 14,2 | 0,386 |

| 70 | 0,21 | 2,4 | 16,4 | 0,272 |

| 95 | 0,21 | 2,6 | 19 | 0,206 |

| 120 | 0,21 | 2,8 | 21 | 0,161 |

What Welding Cable Hybird Resources can offer

As a leading exporter and supplier of welding cable, Hybird Resources supplies welding cable including H01N2-D, H01N2-E, and 0361TQ. Also, we can supply welding cable sheathed by Oil and chemical resistant Polyvinylchloride(PVC).

PVC Welding Cable Rated Voltage is 450/750V, Its working temperature 70℃, Max. The temperature in case of short circuit is 160℃ on the conductor (maximum duration 5 seconds)

PVC Welding Cable Technical Datasheet

| Nominal cross sectional area of conductor | Maximum diameter of wire of conductor | Thickness of covering | Mean overall diameter | Maximum conductor resistance at 20℃ | Conductor Capacity at 60% duty cycle | ConductorCapacity at 35% duty cycle |

| mmq | mm | mm | mm | Ohm/Km | Ampere | Ampere |

| 10 | 0,31 | 1,6 | 6,7 | 1,91 | 108 | 122 |

| 16 | 0,31 | 1,8 | 8,2 | 1,21 | 175 | 230 |

| 25 | 0,31 | 2 | 10,2 | 0,78 | 230 | 300 |

| 35 | 0,31 | 2,2 | 11,6 | 0,554 | 290 | 375 |

| 50 | 0,31 | 2,4 | 13,6 | 0,386 | 365 | 480 |

| 70 | 0,31 | 2,6 | 15,6 | 0,272 | 460 | 600 |

| 95 | 0,31 | 2,8 | 18,2 | 0,206 | 560 | 730 |

| 120 | 0,31 | 3 | 20,4 | 0,161 | 650 | 850 |

| 150 | 0,31 | 3,3 | 24,7 | 0,129 | 750 | 980 |

| 185 | 0,31 | 3,5 | 25,7 | 0,106 | 860 | 1120 |