PV Wire UL4703 Halogen-free Low Smoke for Solar Panel

PV Wire UL4703 Halogen-free Low Smoke for Solar Panel Application

PV Wire UL4703 solar cable intended for the interconnection within photovoltaic systems such as solar panel arrays.For free movable or fixed installation in photovoltaic installation. The cable may be used indoor, outdoor, in earth (please note the laying instruction), in explosion hazard areas in industry and agriculture. The cable is considered to short-circuit and earth-fault safe.

PV Wire is sunlight, ozone, UV, and moisture resistant. Photovoltaic Wire (PV Wire) may be used as wiring for solar panels, as the interconnection wiring of grounded and ungrounded photovoltaic power systems.

Being flame protected with a halogen-free fire retardant system with low smoke properties.these cables are designed for safety in case of fire.

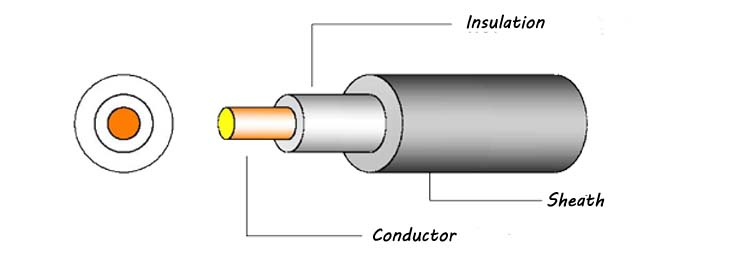

PV Wire UL4703 Halogen-free Low Smoke for Solar Panel Construction

| Conductor material: | Bare/Tinned copper wire strands |

| Insulation: | Halogen-free electronic beam cross-linked compound |

| Insulation: | Halogen-free electronic beam cross-linked compound,Flame retardant |

PV Wire UL4703 Halogen-free Low Smoke for Solar Panel Technical Data

| Rated Voltage U | 600V,1000V,2000V |

| Tested Voltage U0 | U=600V: 18~10AWG,U0=3000V,50Hz,1min 8~2AWG,U0=3500,50Hz,1min 1~4/0AWG,U0=40000,50Hz,1min U=1000V,2000V 18~10AWG,U0=6000V,50Hz,1min 8~2AWG,U0=7500,50Hz,1min 1~4/0AWG,U0=90000,50Hz,1min |

| Rated Temperature | -40 to 90 |

| Flame Test | UL1581 VW-1 |

| Relative Permitivity | UL854 |

| Stability factor | UL854 |

| Sunlight Resistance | UL2556 |

PV1-F EBXL Photovoltaic Solar Cable 600/1000V Specification

| Gauge | Nominal C.S.A | Conductor Construction | 600V Cable O.D | 1000,2000V Cable O.D | Max.Conductor resistance at 20℃ |

| AWG | mm2 | n/mm | mm | mm | Ω/km |

| 18 | 0.823 | 16/0.254 | 4.25 | 5 | 23.2 |

| 16 | 1.31 | 26/0.254 | 4.55 | 5.3 | 14.6 |

| 14 | 2.08 | 41/0.254 | 4.95 | 5.7 | 8.96 |

| 12 | 3.31 | 65/0.254 | 5.4 | 6.2 | 5.64 |

| 10 | 5.261 | 105/0.254 | 6.2 | 6.9 | 3.546 |

| 8 | 8.367 | 168/0.254 | 7.9 | 8.4 | 2.23 |

| 6 | 13.3 | 266/0.254 | 9.8 | 10.3 | 1.403 |

| 4 | 21.15 | 420/0.254 | 11.7 | 11.7 | 0.882 |

| 2 | 33.62 | 665/0.254 | 13.3 | 13.4 | 0.5548 |

| 1 | 42.41 | 836/0.254 | 15.2 | 16.1 | 0.4398 |

| 1/0 | 53.49 | 1045/0.254 | 17 | 17.1 | 0.3487 |

| 2/0 | 67.43 | 1330/0.254 | 18.3 | 18.8 | 0.2766 |

| 3/0 | 85.01 | 1672/0.254 | 19.8 | 20.4 | 0.2194 |

| 4/0 | 107.2 | 2109/0.254 | 21.5 | 22.1 | 0.1722 |

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.