JHSB Submersible Pump Flat Cable

JHSB Submersible Pump Flat Cable Application

This Submersible Pump Flat cable is suitable for various types of the lead wire of submersible motor (lead from underwater to above-water). This product can be equipped with a waterproof joint (it can be supplied completely as request). The features of lead wire are convenient in use, good waterproof property. Even if it exists in external damage, it can also guarantee the motor is not suffered from damage caused by water. It is a new type of waterproof cable.

This cable is intended for use with submersible pumps and irrigation equipment. For wiring only between equipment located at water wellheads and motors of submersible pumps installed in deep wells. As connection cable for submersible electric motors (pumps) for the permanent use in water up to the temperature of 70 °C and to a depth of 600 m. These submersible pump flat cable is ideal for outer installations with medium mechanical load in dry, moist and wet environments but however not suitable for explosive areas. Test certificates of different national and international institutes are available on request.

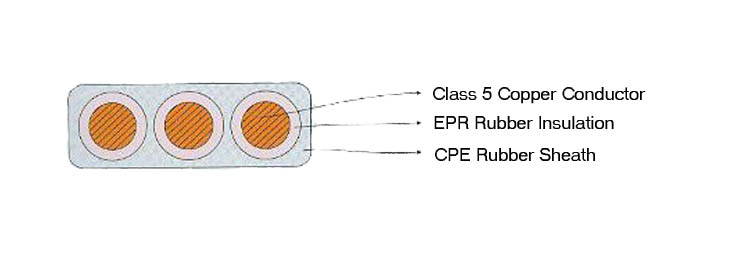

JHSB Submersible Pump Flat Cable Construction

| Conductor | bare copper wire IEC 60228/DIN VDE 0295 Class 5 |

| Insulation | EPR – Ethylene Propylene Rubber |

| Sheath | CPE – Chlorinated Polyethylene Rubber |

JHSB Submersible Pump Flat Cable Technical Data

| Rated Voltage | 300/500V,450/750V,600/1000V |

| Test Voltage | 1.5KV,2.5KV,3.5KV |

| Conductor Working temperature | 85°C |

| Ambient temperature | Fixed:-40°C to 90°C

Mobile:-25°C to 90°C |

| flame retardant | VDE 0482-332-1-2/IEC 60332-1 |

JHSB Submersible Pump Flat Cable Specification

| Conductor | Nominal Core Dia. | Approx. Overall Dimensions of double Sheathed Cable | Conductor Resistance at 20°C (max) | Current rating at 40°C | ||

| Nominal Area in | Nos. & Dia. of wire | 3 Core | 4 Core | |||

| (T x W) Thickness x Width | (T x W) Thickness x Width | |||||

| Sq. mm. | Nos./mm | mm | mm | mm | Ω/km | Amps. |

| 1.5 | 22/0.30 | 3.25 | 6 x 12.8 | 6 x 15.8 | 12.1 | 14 |

| 2.5 | 36/0.30 | 3.84 | 6.4 x 14.6 | 6.5 x 18 | 7.41 | 18 |

| 4 | 56/0.30 | 4.5 | 7.4 x 16.8 | 7.6 x 21 | 4.95 | 26 |

| 6 | 84/0.30 | 5.3 | 7.9 x 18.7 | 7.9 x 24.3 | 3.3 | 31 |

| 10 | 140/0.30 | 6.5 | 9.9 x 23.7 | 9.9 x 29.7 | 1.91 | 42 |

| 16 | 224/0.30 | 8 | 11.4 x 28 | 11.8 x 36 | 1.21 | 57 |

| 25 | 350/0.30 | 10.1 | 14.7 x 35.5 | 14.7 x 45.1 | 0.78 | 72 |

| 35 | 490/0.30 | 11.3 | 16.2 x 39.5 | 16.2 x 50.1 | 0.554 | 90 |

| 50 | 703/0.30 | 13.6 | 18.3 x 45.5 | 18.3 x 58.1 | 0.386 | 115 |

| 70 | 988/0.30 | 15.3 | 20 x 51 | 20 x 66.5 | 0.272 | 143 |

| 95 | 1349/0.30 | 18 | 23.5 x 60 | 23.5 x 77.3 | 0.206 | 165 |

The number of wires is approximate and the wire diameter is nominal. They shall be such as to satisfy the requirements of conductor resistance as per Class 5 of IEC 60228 / DIN VDE 0295 / BS 6360

Standard Packing:Coils 100, 200,300 and 500, 1000m. In wooden drums

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.