GGDURP High Flexible Shield Energy Chain Power Cable

GGDURP High Flexible Shield Energy Chain Power Cable Application

GGDURP High Flexible Shield Energy Chain Power Cable is intended for systems engineering and mechanical engineering, crane and conveyor equipment, power, and supply cable with extremely heavy loads.

GGDURP High Flexible Shield Energy Chain Power Cable is a Highly flexible, screened control cable with TPE core insulation and abrasion and oil-resistant PUR sheath. This cable is of a good combination of quality and compact design, Thin and light. Its Increased durability under harsh conditions thanks to robust PUR outer sheath. This shielded power cable is resistant to contact with many mineral oil-based lubricants, diluted acids, aqueous alkaline solutions, and other chemical media. Its copper braiding screens the cable against electromagnetic interference.

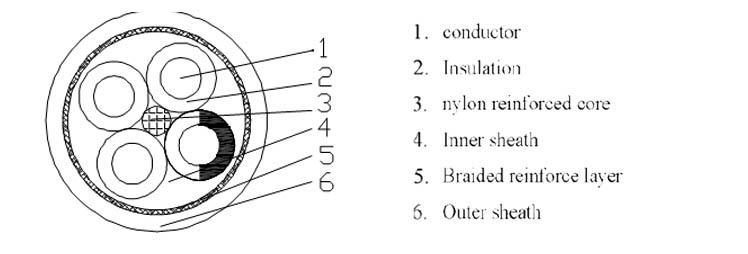

GGDURP High Flexible Shield Energy Chain Power Cable Construction

| Power Conductor | High Flexible, Finely stranded bare copper wire according to IEC60228/VDE0298 Class6 |

| Insulation | TPE Compound |

| Inner Covering | TPU Compound |

| Reinforced Element | Nylon wire/Kevlar Wire braid |

| Shield | High flexural strength copper shield, coverage approx. 90% optical. |

| Outer Sheath | PUR Compound |

Code Design

| Cable for Port machinery | G |

| Reinforced | G |

| For Motor systems | D |

| PUR Sheath | U |

| Flexible Conductors | R |

| Metal braided shield | P |

GGDURP High Flexible Shield Energy Chain Power Cable Technical Data

| Rated Voltage | 600/1000V |

| Min.Ambient temperature | -35℃ |

| Conductor Long time working temperature | 100℃ |

| Min.Bending radius | 6OD |

GGDURP High Flexible Shield Energy Chain Power Cable Specification

| Cross section(mm2) | Conductor construction ( tinned copper) | Nom. OD of Cable(mm) | Max. OD of Cable(mm) | Approx weight(kg/km) |

| 1×4 | 1×126/0.20 | 7.9 | 8.7 | 114 |

| 1×6 | 1×189/0.20 | 8.8 | 9.6 | 146 |

| 1×10 | 1×322/0.20 | 10.1 | 11.1 | 205 |

| 1×16 | 1×513/0.20 | 11.5 | 12.7 | 280 |

| 1×25 | 1×798/0.20 | 13.3 | 14.6 | 399 |

| 1×35 | 1×1121/0.20 | 14.7 | 16.2 | 514 |

| 1×50 | 1×703/0.30 | 16.9 | 18.6 | 693 |

| 1×70 | 1×999/0.30 | 19.6 | 21.2 | 948 |

| 1×95 | 1×1332/0.30 | 21.4 | 23.1 | 1198 |

| 1×120 | 1×1702/0.30 | 23.2 | 25.1 | 1505 |

| 1×150 | 1×2109/0.30 | 25.6 | 27.6 | 1835 |

| 1×185 | 1×1443/0.40 | 28.2 | 30.5 | 2206 |

DISCLAIMER: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.