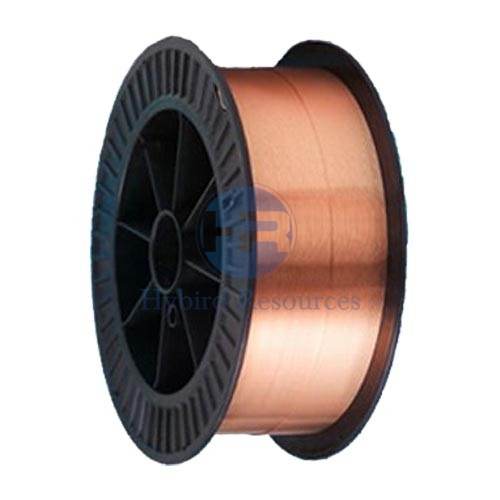

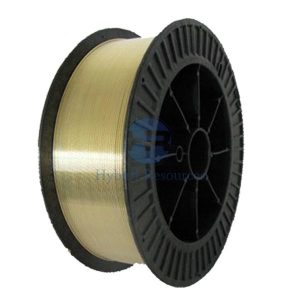

ERCu Copper Alloy Welding Wire

ERCu Copper Alloy Welding Wire APPLICATION

ERCu is a deoxidized copper alloy developed to provide dense, high-quality deposits with relatively high electrical conductivity for use in joining and overlay with the inert-gas processes.

ERCu spooled wire and filler metal rod are used primarily to fabricate deoxidized copper and repair weld copper castings with the gas metal-arc and gas tungsten-arc processes. It may also be used to weld galvanized steel and deoxidized copper to mild steel where high strength joints are not required.

ERCu spooled wire and filler metal rod are used to overlay surfaces to resist corrosion. ERCu is typically used for billet molds, conductor rolls, heater elements, copper sculptures, steel mill electrode holders, bus bars, and copper connectors.

Physical performance and mechanical properties:

Solid-phase 1020 DEG C density 8.9kg/dm Extension rate of 30-40%

liquidus 1050 DEG C tensile strength 210-220N/mm2, Brinell hardness 60HB

ERCu Copper Alloy Welding Wire Chemical Composite

| Chemical Composite (%) | |||||

| Standards | ISO 24373 | GB/T9460 | BS EN14640 | AWS A5.7 | DIN1733 |

| Class NO. | Cu1898 | SCu1898 | Cu1898 | C18980 | 2.1006 |

| Alloy NO. | CuSn1 | CuSn1 | CuSn1 | ERCu | SG-CuSn |

| Cu | Min 98 | Min98 | Bal. | Min 98 | Bal. |

| Al | 0.01 | Max 0.01 | 0.01 | 0.01 | Max 0.01 |

| Fe | – | – | 0.05 | 0.50 | Max 0.05 |

| Mn | 0.50 | Max 0.5 | 0.1~0.5 | 0.50 | 0.1~0.5 |

| Ni | – | – | 0.3 | – | Max 0.3 |

| P | 0.15 | Max 0.15 | 0.02 | 0.15 | Max 0.02 |

| Pb | 0.02 | Max 0.02 | 0.02 | 0.02 | Max 0.01 |

| Si | 0.5 | Max 0.5 | 0.5 | 0.5 | 0.1~0.5 |

| Sn | 1.0 | Max 1.0 | 0.5~1.0 | 1.0 | 0.5~1.0 |

| As | – | – | 0.05 | – | Max 0.05 |

| Other Total | 0.5 | Max 0.5 | 0.1 | 0.5 | Max 0.1 |

Reviews

There are no reviews yet.