H05VVC4V5-F NYSLYCYÖ Copper Braiding PVC Control Cable

H05VVC4V5-F NYSLYCYÖ Copper Braiding PVC Control Cable Application

These H05VVC4V5-F cables are used as screened termination and connection cable in the control, measuring, and signal technology. The copper braiding optimizes protection against external interferences, like electromagnetic fields and stray frequencies. Suitable as a signal and impulse cable for control and inspection of industrial plants, machinery, and working processes.

These cables are used for flexible use for medium mechanical stresses with free movement without tensile stress or forced movements in dry, moist and wet rooms but not suitable for open air. These are designed as control and connecting cables to machines, tool machineries, conveyor belts and production lines. These cables are not effected to the chemical influences. Cables for moist and wet rooms, specially used for machines in breweries, bottling plants and car washing stations. These cables may be allowed to move once installed provided that the cables are not mechanically stressed during movement. The interconnection of parts of machines used for manufacturing purposes including machine tools where some degree of protection against electromagnetic interference is required.

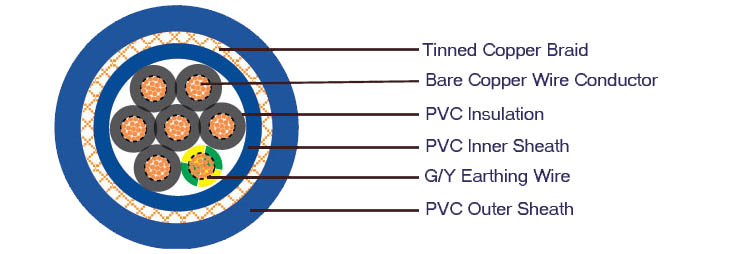

H05VVC4V5-F NYSLYCYÖ Copper Braiding PVC Control Cable Construction

| Conductor | Fine bare copper strands,Strands to VDE-0295 Class-5, IEC 60228 Class-5 |

| Insulation | PVC insulation T12 to DIN VDE 0281 part 1,Cores to VDE-0293 colors,Green-yellow grounding (3 conductors and above) |

| Inner Sheath | PVC inner sheath TM2 to DIN VDE 0281 part 1 |

| Screen | Tinned copper braided shielding, covering approx. 85% |

| Outer Sheath | PVC outer jacket TM5 to DIN VDE 0281 part 1 |

H05VVC4V5-F NYSLYCYÖ Copper Braiding PVC Control Cable Technical Data

| Working voltage | 300/500v |

| Test voltage | 2000volts |

| Flexing bending radius | 10 x OD |

| Static bending radius | 5 x OD |

| Flexing Temperature | -5 oC to +70 oC |

| Static temperature | -40 oC to +70 oC |

| Flame retardant | IEC 60332.1 |

| Insulation resistance | 20 MΩ x km |

H05VVC4V5-F NYSLYCYÖ Copper Braiding PVC Control Cable Specification

| Number of cores and

nominal cross section |

Copper figure | Conductor construction | Approx.

Overall diameter |

Approx.Weight |

| mm2 | kg/km | mm | mm | kg/km |

| 3 G 0.75 | 53 | 24 x 0.21 | 8.8 | 125 |

| 4 G 0.75 | 66 | 24 x 0.21 | 9.6 | 147 |

| 5 G 0.75 | 82 | 24 x 0.21 | 10.3 | 172 |

| 7 G 0.75 | 112 | 24 x 0.21 | 12.2 | 235 |

| 12 G 0.75 | 168 | 24 x 0.21 | 14.5 | 354 |

| 18 G 0.75 | 229 | 24 x 0.21 | 16.9 | 478 |

| 3 G 1 | 78 | 32 x 0.21 | 9.3 | 140 |

| 4 G 1 | 90 | 32 x 0.21 | 9.9 | 165 |

| 5 G 1 | 106 | 32 x 0.21 | 10.9 | 195 |

| 7 G 1 | 132 | 32 x 0.21 | 12.9 | 271 |

| 12 G 1 | 202 | 32 x 0.21 | 15.4 | 405 |

| 18 G 1 | 276 | 32 x 0.21 | 17.7 | 548 |

| 3 G 1.5 | 99 | 30 x 0.26 | 10.4 | 180 |

| 4 G 1.5 | 121 | 30 x 0.26 | 11.3 | 217 |

| 5 G 1.5 | 135 | 30 x 0.26 | 12.6 | 267 |

| 7 G 1.5 | 175 | 30 x 0.26 | 14.9 | 379 |

| 12 G 1.5 | 265 | 30 x 0.26 | 17.6 | 538 |

| 18 G 1.5 | 400 | 30 x 0.26 | 20.5 | 743 |

| 3 G 2.5 | 154 | 50 x 0.26 | 12 | 246 |

| 4 G 2.5 | 170 | 50 x 0.26 | 13.3 | 316 |

| 5 G 2.5 | 208 | 50 x 0.26 | 14.6 | 383 |

DISCLAIMER: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.