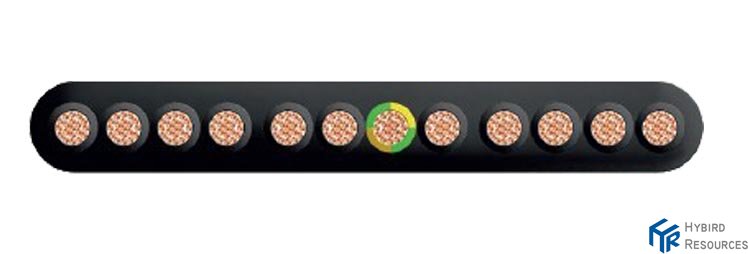

H05VVH6-F Elevator Flat Control Cable

H05VVH6-F Elevator Control Flat Cable Application

H05VVH6-F Elevator Flat Control Cable is mainly used as a trailing cable for crane installations, floor conveyor systems, elevator control cables, shelf control units and in supply lines for moving machine parts. The flat construction allows these cables to be stacked for applications where space is at a minimum and require a smaller bending radius over that of round cables. Suitable for installations in dry and damp rooms. The outer PVC jacket is extensively resistant to oil, fat, acid, and lye.

The cable uses a special structure design, and has a long service life, can provide the overall electrical control under the longer length of the suspension, and can withstand greater mechanical shock stress. The product with steel wire is optional to bear cable core and can be for the long-distance flying occasions.

The flat construction is particularly suitable for use in overhead crane and material handling systems and for applications where space is limited.

H05VVH6-F Elevator Flat Control Cable Construction

| Conductor: | Flexible plain copper |

| Stranding: | According to VDE 0295, class 5, IEC 60228 |

| Insulation: | PVC |

| Core Marking: | Up to 5 cores colour coded in accordance to VDE 0293;7 and more cores number coded with a green/yellow earth |

| Outer Sheath: | Black PVC |

H05VVH6-F Elevator Flat Control Cable Technical Data

| Working voltage | 300/500 V |

| Test voltage | 2KV |

| Bending radius | 10 × cable Ø |

| Flexing temperature | – 5ºC to + 70ºC |

| Static temperature | -40ºC to +70ºC |

| Flame retardant | test class B according to VDE 0472 part 804, IEC 60332-1 |

| Insulation resistance | 20 MΩ x km |

H05VVH6-F Elevator Flat Control Cable Specification

| No. of Cores x Nominal | Nominal Conductor | Nominal Thickness | Nominal Overall | Nominal |

| Cross Sectional Area | Diameter | of Insulation | Diameter | Weight |

| # x mm² | mm | mm | mm | kg/Km |

| 4 x 0.75 | 1.2 | 0.6 | 4.2 x 12.6 | 90 |

| 8x 0.75 | 1.2 | 0.6 | 4.2 x 23.2 | 175 |

| 12x 0.75 | 1.2 | 0.6 | 4.2 x 33.8 | 260 |

| 18x 0.75 | 1.2 | 0.6 | 4.2 x 50.2 | 380 |

| 24x 0.75 | 1.2 | 0.6 | 4.2 x 65.6 | 490 |

| 4 x 1.00 | 1.4 | 0.7 | 4.4 x 13.4 | 105 |

| 5×1.00 | 1.4 | 0.7 | 4.4 x 15.5 | 120 |

| 8 x 1.00 | 1.4 | 0.7 | 4.4 x 24.8 | 205 |

| 12x 1.00 | 1.4 | 0.7 | 4.4 x 36.2 | 300 |

| 18x 1.00 | 1.4 | 0.7 | 4.4 x 53.8 | 450 |

| 24x 1.00 | 1.4 | 0.7 | 4.4 x 70.4 | 590 |

DISCLAIMER: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.