H07VVH6-F Flat PVC Festoon Cable

H07VVH6-F Flat PVC Festoon Cable Application

H07VVH6-F is widely used on festoon systems supplying power and control to all types of moving machinery. This cable is suitable for dry, wet, and moist rooms and is used in conveyor and hoisting equipment, etc, and as feed cable for mobile machine components. These cables have a significantly smaller bending radius compared to round cables, The flat construction allows cables to be stacked for applications where space is limited.

H07VVH6-F cable is Oil, acid, and alkaline resistant, for indoor and outdoor applications, Moisture, UV, and ozone resistance. Flame-retardant according to IEC 60 332 part 1.

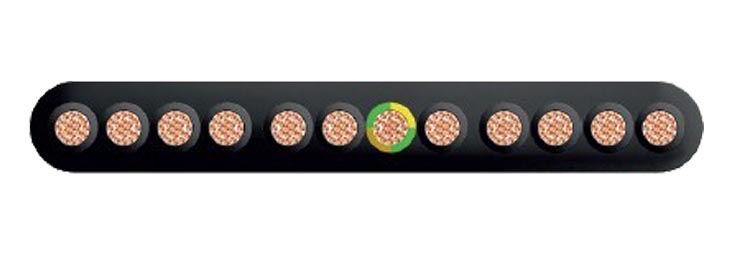

H07VVH6-F Flat PVC Festoon Cable Construction

| Conductor: | Flexible plain copper |

| Stranding: | According to VDE 0295, class 5, IEC 60228 |

| Insulation: | PVC |

| Core Marking: | Up to 5 cores color coded in accordance to VDE 0293;7 cores and more are number coded with a green/yellow earth |

| Outer Sheath: | Black PVC |

H07VVH6-F Flat PVC Festoon Cable Technical Data

| Nominal voltage | Uo/U:450/750 V |

| Maximum operating voltage in AC systems | Um:750 V |

| Test voltage | 2.5 kV – 50 Hz in AC |

| Max. temperature at the conductor : | – in service:+ 70 °C – in short circuit:+ 150 °C |

| Max. surface temperature : | – fixed installation:– 35 °C up to + 60 °C – mobile operation:– 25 °C up to + 60 °C |

| Tensile stress of the conductor | static:15 N/mm2 dynamic:30 N/mm2 |

| Tests | Bending test |

| Travelling Festoon speed | up to 120 m/min |

H07VVH6-F Flat PVC Festoon Cable Specification

| Number of cores and nominal cross section |

Copper index | Conductor construction |

Overall size | Approx. Weight |

| mm2 | kg/km | mm | mm | kg/km |

| 4 G 1,5 | 60,0 | 30 x 0,26 | 5,0 x 15,0 | 150,0 |

| 5 G 1,5 | 75,0 | 30 x 0,26 | 5,0 x 18,0 | 180,0 |

| 7 G 1,5 | 105,0 | 30 x 0,26 | 5,0 x 27,0 | 265,0 |

| 8 G 1,5 | 120,0 | 30 x 0,26 | 5,0 x 29,0 | 295,0 |

| 10 G 1,5 | 150,0 | 30 x 0,26 | 5,0 x 36,0 | 355,0 |

| 12 G 1,5 | 180,0 | 30 x 0,26 | 5,0 x 41,0 | 415,0 |

| 4 G 2,5 | 100,0 | 50 x 0,26 | 5,7 x 18,5 | 250,0 |

| 5 G 2,5 | 125,0 | 50 x 0,26 | 5,7 x 22,0 | 280,0 |

| 7 G 2,5 | 175,0 | 50 x 0,26 | 5,7 x 33,5 | 385,0 |

| 8 G 2,5 | 200,0 | 50 x 0,26 | 5,7 x 37,0 | 430,0 |

| 12 G 2,5 | 300,0 | 50 x 0,26 | 5,7 x 51,0 | 630,0 |

| 4 G 4 | 160,0 | 56 x 0,31 | 6,9 x 21,5 | 320,0 |

| 5 G 4 | 200,0 | 56 x 0,31 | 6,9 x 26,0 | 390,0 |

| 7 G 4 | 280,0 | 56 x 0,31 | 6,9 x 38,0 | 560,0 |

| 4 G 6 | 240,0 | 84 x 0,31 | 7,6 x 24,5 | 430,0 |

| 5 G 6 | 300,0 | 84 x 0,31 | 7,6 x 29,5 | 530,0 |

| 4 G 10 | 400,0 | 80 x 0,41 | 9,6 x 31,0 | 690,0 |

| 4 G 16 | 640,0 | 128 x 0,41 | 10,9 x 35,5 | 970,0 |

| 4 G 25 | 1.000,0 | 200 x 0,41 | 12,7 x 41,5 | 1.405,0 |

| 4 G 35 | 1.400,0 | 280 x 0,41 | 15,7 x 49,0 | 2.035,0 |

| 4 G 50 | 2.000,0 | 400 x 0,41 | 19,1 x 61,5 | 3.000,0 |

DISCLAIMER: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.

Reviews

There are no reviews yet.